Use cases

Incorporating robots creates new ways of working.

Find inspirations for new ideas through different success stories.

-

ManufacturingPalletizing

-

![[두산 로봇 솔루션] 레이저 용접 로봇](/images/main/youtube-thumbnail-2.webp)

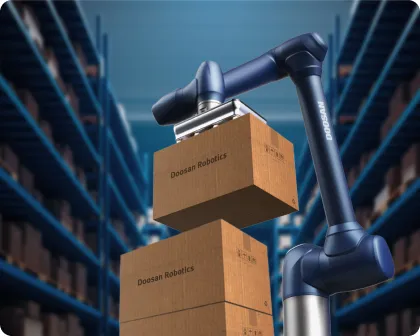

ManufacturingLaser Welding

-

![[Doosan Cobot Solution] 샌딩 (Sanding)](/images/main/youtube-thumbnail-3.webp)

ManufacturingSanding

-

![[현장 적용 사례] M0617 - 공작기계 보조 작업 / 두산 협동로봇 in 신성정밀](/images/main/youtube-thumbnail-4.webp)

ManufacturingMachine Tending

-

ServiceDr.Presso

-

![[Doosan Cobot Solution] 학교 단체급식 튀김 로봇 솔루션](/images/main/youtube-thumbnail-6.webp)

ServiceDeep Frying

-

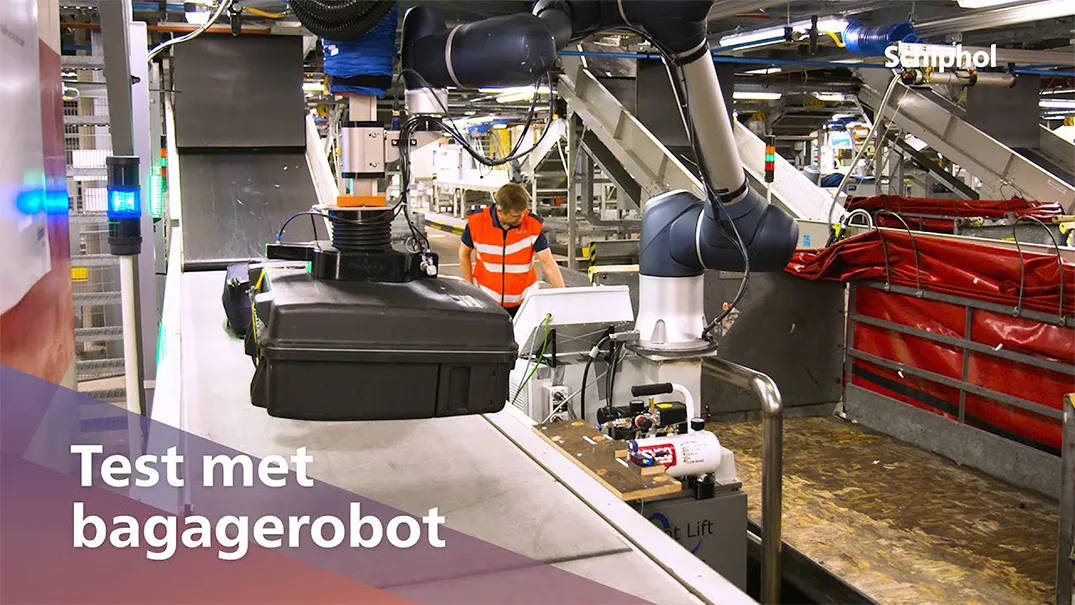

ServiceAirport Luggage Handling

-

![[Doosan Cobot Solution] 전기차 충전 로봇 솔루션 (with LG Electronics)](/images/main/youtube-thumbnail-8.webp)

ServiceEV Charging

-

![[Doosan Cobot Solution] 입생로랑 팝업 스토어](/images/main/youtube-thumbnail-9.webp)

Events & ExhibitsYves Saint Laurent Popup Store Event

-

Events & ExhibitsDior Photo Shoot Event

-

![[두산 로봇 솔루션] 마산 로봇랜드 (Doosan X AMR Labs)](/images/main/youtube-thumbnail-11.webp)

Events & ExhibitsMasan Robot Land Exhibit

-

Events & ExhibitsMedia Art Exhibit

Our Clients

Leading companies of 50 countries around the world

incorporated Doosan robots and

achieved

cost reduction.

Solutions

View All Solutions

Service

Dr.Presso

Cobot from Doosan Robotics is Korea's No. 1 collaborative robot with outstanding safety

and convenience,

and the combination with top-tier coffee machine allows it to deliver high-quality

service up to par with luxury coffee shops while its intuitive interface allows easy

maintenance.

Industrial

Palletizing

The palletizing solution is composed of cobot specializing in organizing

goods onto pallets in logistics and

transportation sectors. Automated palletizing maximizes productivity and safety.

Training

Training Kit

Doosan Robotics Training Kit provides opportunities of becoming a certified cobot

engineer.

It is the first step in understanding how to teach cobots directly and how to

collaborate with operators.

Products

The World's Largest

Cobot Lineup

-

Purchase Inquiry

Thinking about incorporating a robot?

Receive 1:1 consulting from an expert. -

Find Nearest Dealer

Find information

about dealers nearby. -

Doosan Robot Training

Improve your robot operation

skills through online/offline training. -

A/S Apply

Robot experts provide customer A/S

365 days a year.