Improved Productivity

High-performance torque sensor ensures greater precision for improved quality and productivity

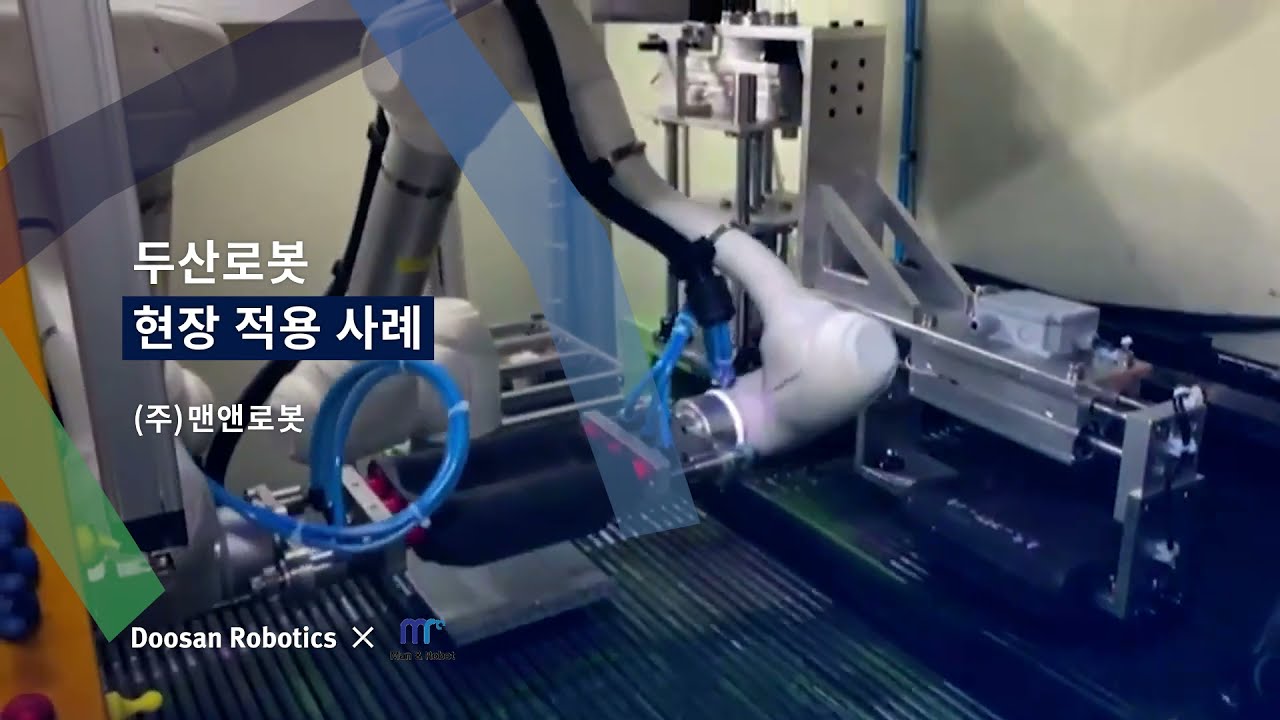

Doosan Inspection Solution performs visual inspection tasks using cameras and difficult precision inspections through innovative force control technology and motion control algorithms.

High-performance torque sensors integrated in all 6 joints simulate an operator’s delicate sense of touch. It effectively supports high-load gauge inspections and precise weight detection to identify defective products. It also automates repetitive inspection tasks in conjunction with various sensors to further improve inspection quality.

As such, Doosan Inspection Solution can be incorporated into various applications, from visual inspection of precision electronics such as smartphone batteries to precision inspection of power generation equipment. It delivers the highest inspection quality alongside outstanding operational efficiency to the customer.

High-performance torque sensor ensures greater precision for improved quality and productivity

Initial investment cost recouped within 2 years (on average)

Operation without fences possible in narrow spaces, requires no layout changes

With the industry's highest safety standards, seamless and secure collaboration with operators is ensured

SMR (Small Module Reactor) Non-destructive Inspection

Parts Inspection

Ventilated Seat Headrest Inspection

Vehicle Inspection

Thinking about incorporating an inspection solution?

Leave an inquiry and one of our experts will reply as soon as possible.