Use cases

Durch die Einbindung von Robotern

entstehen neue Arbeitsweisen.

Finden Sie mit vielen Erfolgsgeschichten die richte Inspiration für neue Ideen.

-

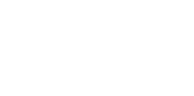

HerstellungPalettieren

-

![[두산 로봇 솔루션] 레이저 용접 로봇](/images/main/youtube-thumbnail-2.webp)

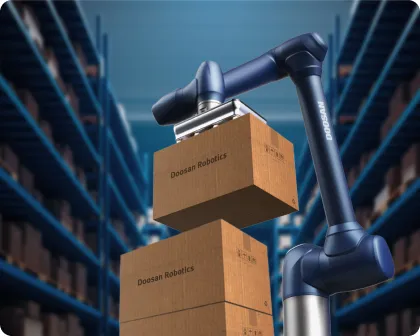

HerstellungLaserschweißen

-

![[Doosan Cobot Solution] 샌딩 (Sanding)](/images/main/youtube-thumbnail-3.webp)

HerstellungBesanden

-

![[현장 적용 사례] M0617 - 공작기계 보조 작업 / 두산 협동로봇 in 신성정밀](/images/main/youtube-thumbnail-4.webp)

HerstellungMaschinenbedienung

-

DienstleistungenDr.Presso

-

![[Doosan Cobot Solution] 학교 단체급식 튀김 로봇 솔루션](/images/main/youtube-thumbnail-6.webp)

DienstleistungenFrittieren

-

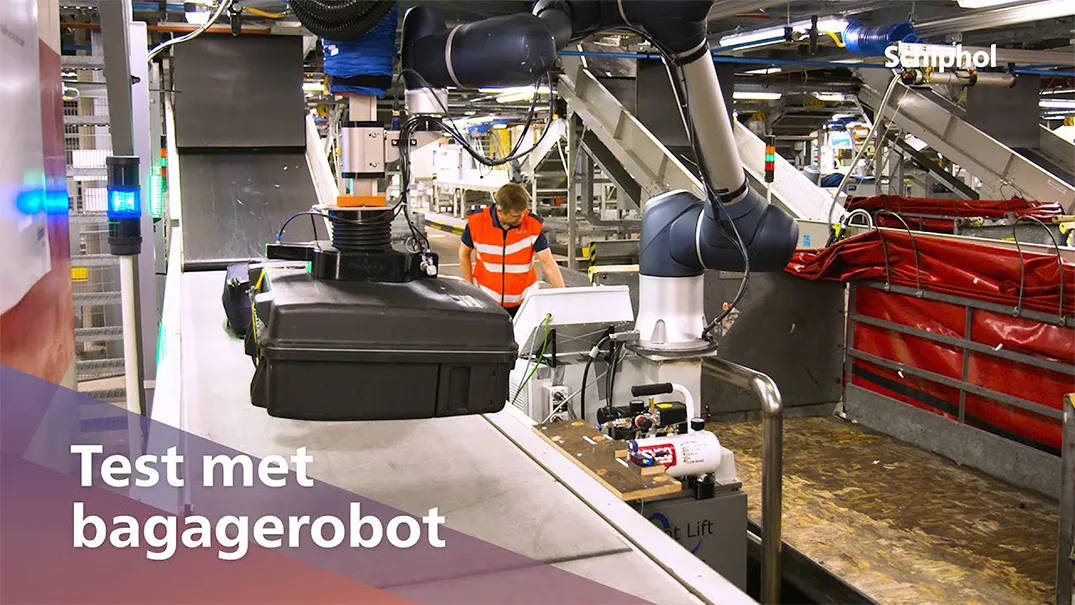

DienstleistungenFlughafen-Gepäckabfertigung

-

![[Doosan Cobot Solution] 전기차 충전 로봇 솔루션 (with LG Electronics)](/images/main/youtube-thumbnail-8.webp)

DienstleistungenAufladen von Elektrofahrzeugen

-

![[Doosan Cobot Solution] 입생로랑 팝업 스토어](/images/main/youtube-thumbnail-9.webp)

Veranstaltungen

& AusstellungenYves Saint Laurent Popup Store Event -

Veranstaltungen

& AusstellungenDior Photo Shoot Event -

![[두산 로봇 솔루션] 마산 로봇랜드 (Doosan X AMR Labs)](/images/main/youtube-thumbnail-11.webp)

Veranstaltungen

& AusstellungenMasan Robot Land Ausstellung -

Veranstaltungen

& AusstellungenMedia Art Ausstellung

Our Clients

Führende Unternehmen aus 50 Ländern auf der ganzen Welt

integrierten Doosan-Roboters und

erzielten Kostenreduzierung.

Solutions

Alle Lösungen ansehen

Dienstleistungen

Dr.Presso

Cobot von Doosan Robotics ist Koreas kollaborativer Roboter Nr. 1 mit herausragender Sicherheit und Komfort. Die Kombination mit einer erstklassigen Kaffeemaschine ermöglicht es ihm, einen qualitativ hochwertigen Service zu liefern, der dem von Luxus-Cafés in nichts nachsteht, während seine intuitive Schnittstelle eine einfache Wartung ermöglicht.

Industrie

Palletizing

Die Palettierlösung besteht aus einem Cobot, der sich auf die Organisation von Waren auf Paletten in den Bereichen Logistik und Transport spezialisiert hat. Die automatisierte Palettierung maximiert die Produktivität und Sicherheit.

Training

Training Kit

Das Doosan Robotics Training Kit bietet die Möglichkeit, ein zertifizierter Cobot-Ingenieur zu werden. Dies ist der erste Schritt, um zu verstehen, wie man Cobots direkt anlernt und wie man mit den Bedienern zusammenarbeitet.

Products

Das größte

Cobot-Angebot der Welt